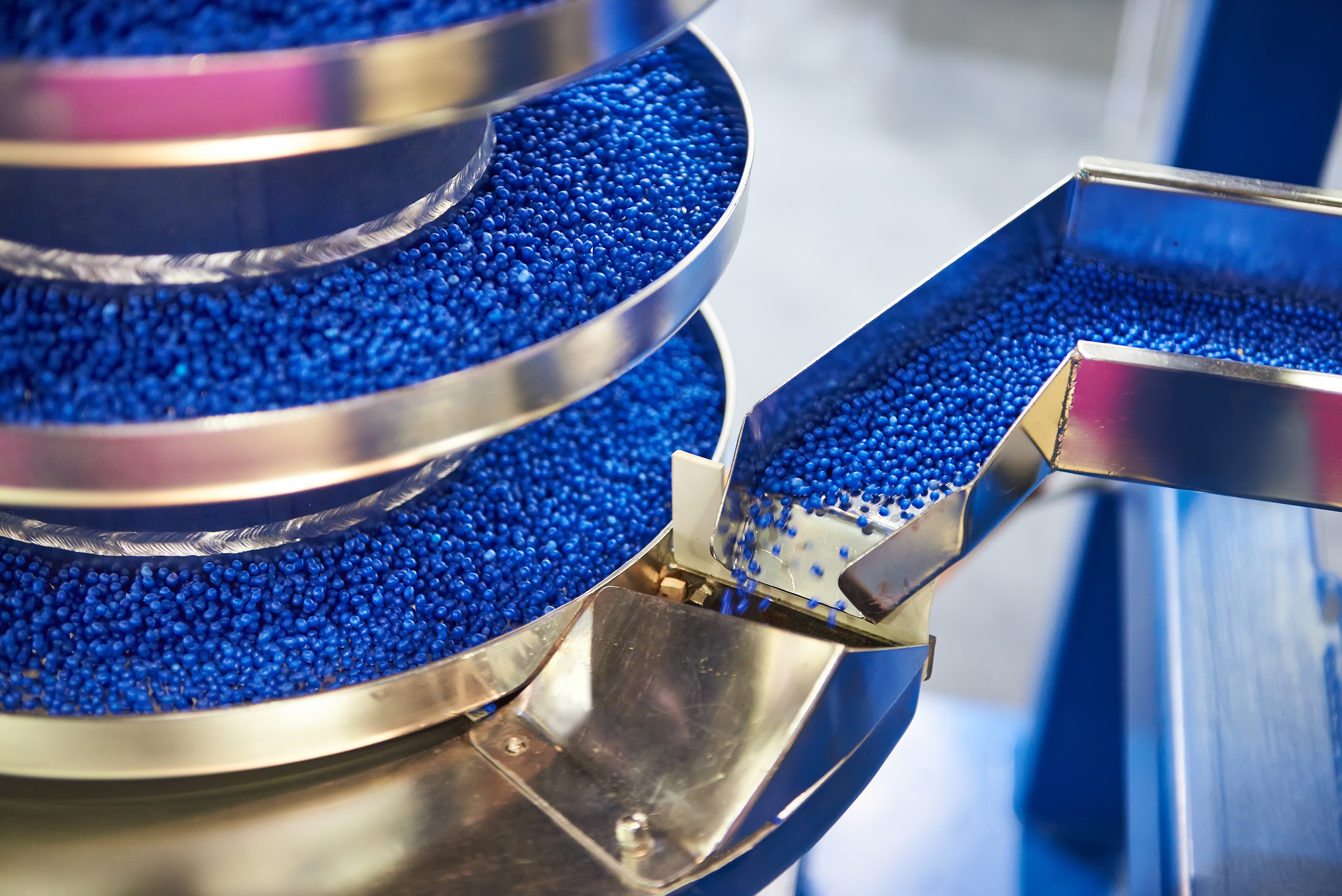

Norlin Compounding produces over 3,500 metric tonnes per year from its 30,000 sq ft manufacturing facility in Bolton.

It worked with Made Smarter to identify and invest in technology which would automate and control the blending process, while giving it real-time visibility of the key data which integrated with its ERP systems.

The outcome has been a 15% increase in productivity, better real-time control of blending, and improved its quality assurance.

Case Study - Norlin CompoundingOver the last 10 years we have been on a journey to incrementally improve the quality of our products, track our throughput and identify potential efficiencies through data capture and analysis.

Working with Made Smarter has been a great experience. The team were extremely knowledgeable and helped us get to where we needed to be, a lot quicker.

Jonathan Holland, Commercial Director

Launched in 1981, Norlin started life supplying compounded polymers to a variety of sectors including household brands, such as Coca-Cola and Fisher Price Toys.

A shift towards manufacturing more technical and specialised polymers for the medical sector 10 years ago, prompted a drive to improve processes to increase its efficiency and quality, and triggered Norlin’s digital transformation.

To remain competitive in a global market, Norlin wanted to capitalise on the opportunities of technology and digital tools to further improve quality and control over its processes. It set its sights on upgrading its blending process.

Jonathan said: “Working with Made Smarter and its digital transformation workshop process we explored the wide-ranging opportunity that digital manufacturing offers, and identified that we needed to continue to strive for a more consistent product and increase the real-time visibility of our blending processes to help us to achieve that. This meant removing some of the manual interventions for a more automated and digital approach where we had access to continuous data.”

Norlin have invested in new gravimetric blending technology that allows for digital integration with their ERP system. Software controls the material conveying and blending processes such as product formulations and material dosing.

Live diagnostics show material usage and diagnostic reports for every cycle or batch produced, which greatly enhance quality assurance and product traceability.

The increased blending capacity has improved productivity by 15% and aided business growth.

It has also increased quality. High precision dosing through these new systems has increased product homogeneity which means Norlin achieves much lower deviations of around +/-0.1% against customer specifications.

Because the blender measures data on a continuous basis versus programmed recipes, Norlin gets full visibility and data capture for its quality management system, which is important for new customers.

Live diagnostics has been a huge step forward in batch traceability and also alerts Norlin to potential problems sooner in the cycle.

Existing operators have been upskilled to use digital technologies as part of the work process.

Jonathan said: “The investment enables us to know what is happening at any given time, capture the data, store it, and leverage it to make further gains.

“It is the automation and access to data that we didn't have before that has been the big change for us. We can improve processes and products with the data to back us up.”

The investment is the first major step to digitising and capturing shop floor data in a more systematic way, which is all part of Norlin’s drive to continuous improvement.